Trout Creek Lumber Co.

|

Standard gauge, 60 and 70-lb rail Headquarters: Stamps, Ark. Mill Location: Trout, LA (LaSalle Parish) Mill Capacity: 150,000 ft/day in 1912 Years of Operation: 1905-1930 Miles Operated: 20 miles in 1927 Locomotives Owned: |

Also see: Equipment:

|

Click Map for Larger Version |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

History by Tony Howe: Trout

Creek Lumber Co. was the first of three large sawmills in the Jena area

built by the William Buchanan lumber interests as he pushed construction of

his Louisiana & Arkansas Railway towards Natchez just after the turn of

the century. Buchanan operated the huge Bodcaw Lumber Co. at Stamps,

Arkansas and at least two large mills in Louisiana, Minden Lumber Co. at

Minden and Pine Woods Lumber Co. at Springhill, before starting the Trout

Creek Lumber Co. The

Trout Creek cut out in October 1929, and the mill was sold to the Louisiana

Delta Hardwood Lumber Co. on 1-2-1930. This sale also included “2 Baldwin

locomotives, 2 American log loaders, 65 log cars, 1 box car, 1 water car,

and 1 Chevrolet motor truck, and 17 track miles of 45-lb rail.”

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A History of Trout, Louisiana -Revised 10-04 By Jack M. Willis

Part I

Trout, Louisiana is a mere umbra of its former years when it was the opulent, crown jewel of the Buchanan Lumbering Dynasty, with it's location lying west of Jena, LA on a "dogleg" on US Highway 84, and this is probably

the only highway feature of its kind found on the whole stretch of roadway between Sacramento, California and its terminus at Augusta, Georgia. This particular section of the highway was built to dovetail with streets already

laid out by the Buchanan engineer Mr. Herbert N. Tannehill in 1907. Though the original mill has been shut down for over 70 years, a good number of the old, identical, gray hued houses still occupy their ordained station in

life.

Around 1895, on horseback (there were no roads, only trails and bridle paths) William Buchanan formerly of Stamps, Arkansas had ridden in to what was then Catahoula Parish, scouting out a vast yellow pine forest he had had

knowledge some years earlier. Prior to the invasion of the tracks of the Louisiana and Arkansas Railroad, several tribes of Native Americans occupied the area, with one historic account stating that two different chiefs ruled

the tribes and that the two chiefs had died on the same day.

Buchanan was bent on expanding the empire he had begun in Stamps, Arkansas starting with the Bodcaw milling operation he had purchased from C.T. Crowell officially on January 14,1889, expanding southward to

Springhill, Louisiana (formerly Barefoot, LA) where he established the Pine Woods Lumber Company in 1894. The next move some 30 miles south to the town of Minden, Louisiana was in 1901, and a year later his "logging line"

chugged into Winnfield, Louisiana, and took time on his way to Trout to absorb Grant Timber and Manufacturing Co. interests near Selma, Louisiana. In a span of fourteen years Buchanan had established five major lumber mills

across the Deep South, followed two years later adding the Good Pine mill and eight years later the Tall Timber mill was added to the fold.

The main reason for locating a new mill in Trout, was the availability of water, the prime prerequisite for lumber milling operations; that and timber. Trout was located geographically in the center of a Mother Lode of

virgin, longleaf pine timber. The mill name came from its location on the headwaters of Trout Creek with this stream probably having been so named by J.P. Ward when he stopped off and settled downstream at White Sulphur

Springs around 1830, but actual construction of the mill didn't start until sometime in 1903. Buchanan, in making his initial long range plans, envisioned taking 70 years to "cut out" the virgin longleaf forests, and

accomplishing this venture from the Trout mill only.

The Best Laid Plans-All of this long range planning was nullified by the Louisiana Legislature in1905, with this legislative body deciding to from extract something from the timber companies currently ravishing Louisiana's

forests raw materials, and shipping the finished products out of state for huge profits. The imposition of ad valorem tax laws would necessitate the later construction of Good Pine and Tall Timber mills in1906 and 1912

respectively to shorten the taxation period.

The milling process had to be established first, because it had to be in operation to furnish lumber with which to build the businesses and houses necessary for the labor forces to function. Mr. Herbert N. Tannehll drove

the first stake to initiate mill construction. He was on loan from the L.& A. Railroad, an operation totally owned by William Buchanan himself and stayed until the planer mill operation was finished, doing all the

engineering for the company.

When the Trout Creek Lumber Company opened the company store/commissary, Ned Kiser was the store manager; Charley North was the office manager, a

Swede from Wisconsin by the name of Babstubner was the mill foreman, and Ben Ezell was deputy sheriff.

The Trout Post Office was established in the back of the store and a Miss Tucker was the Post Mistress, Dr. I.N. Adams was the first company doctor and Mr. W.S. Ellard from Stamps, Arkansas relocated to Trout to

assume the position of log scalar.

The first building erected in Trout was the train depot, because it was necessary to have as a staging area for mill equipment arriving by train daily. Some day's three trips were made to and from Paxton, Louisiana at the

juncture with the Southern Pacific line, where materials were offloaded from trains running from Kansas City to New Orleans.

The mill proper was completed and ready to go on line in 1904.The first two carloads of mules were purchased in St. Louis, Missouri in December of 1904 for rail shipment to Trout. J. A. Buchanan of Texarkana was manager of

the mill. William Buchanan, his valued brother-in-law W.T. Ferguson, his brother J. A., and the Brown brothers, Thomas and William, were the principle owners of the foundling lumbering empire. Two "flatheads" named

Masters and Warner started logging operations in the spring of 1905, with the felling of the first tree; the name flathead being derived from a pine borer with a seemingly flat head, which was indigenous to southern forests.

As of 1890 when the partnership was formed, William Buchanan was only 40 years old, and the team now in 1905 was on the threshold of what William Buchanan had been laying the groundwork for, for some 15 years, and at this

time Sam Finley and Jim Kitchens were brought on board to operate the mill. The Trout mill only sawed one log at a time, forming a single line of different phases until the ending up with the finished product. The most

important pieces of equipment were the carriage and the band saw, which worked against the carriage and was called the "head rig" because they worked along side of each other to produce slabs that would ultimately be

converted to boards down the line.

Immediate construction was started on the planer operation and dry kilns. The kilns were huge concrete buildings with miles of switchback steam pipes on the floor levels and ceilings, and when lumber would come off the

"green chain", it was stacked upon a railway-type car, rolled into the kiln where it would bake, sometimes for days. When it was deemed sufficiently dried and appearing almost scorched, it would then be transported over to

the planing operation. After four months of hard work the planer mill was completed and the company began to manufacturing and shipping lumber.

The mill had enjoyed its successes for about 15 months, when suddenly one night the whole operation caught fire and burning to the ground on June 8th, 1906. It was hastily rebuilt on the original foundation, and in about

four months, operations were begun anew.

A turpentine distillery was constructed about a mile north of where the town would begin to materialize about a year later, with the Buchanan interests operating it until about1909 when it was deemed not economically

feasible, shut down and dismantled. People residing on the north side of Trout during it's operation stated that when the wind was right, the fumes from the distillery would "curl the hair in your nose."

A History of Trout, Louisiana -Revised 10-04

Part II

Trout Creek Lumber Company cranked up their milling operations officially with the felling of the first log on March 01,1905 by "flatheads" Masters and Warner,with the first log being sawn the same day in

commemoration. When finished lumber was being produced according to the dictates of management, the powers-that-be then initiated efforts to fabricate a company town, with company engineer H. N. Tannehill laying out

the town proper, and crews of craftsmen supervised by one John Casey erected the buildings. In the first consignment there were 60 houses constructed for white

residents, whose only condition to live in one of the houses was that breadwinner be employed at the mill. A company house with electricity and water cost $5.00 a month, no taxes. Standard housing rental was $3.00, and

on up to the most expensive at $10.00. This village would eventually swell to 108 dwellings, a Company Commissary, a Masonic Lodge, a Methodist Church, a combination Doctor's Office and barbershop, U.S. Post Office

and a Hotel. John Casey had also constructed the Methodist Episcopalian Church in 1906 and first pastor was W.F. Roberts. A painting contractor from Monroe, La. named Turrentine painted all of the buildings. The Colored

quarters were

were to be painted a dull red.

The mill town of Trout was literally carved out of the yellow pine forest. About the only description that suited this first town in the area, was that it was practical from a company viewpoint. The dwellings were all

one story, with 12-foot ceilings and the reason being was that the mill didn't saw any lumber shorter than 12 feet, thus by sealing up the wall with 12 foot long boards, this saved sawing off the already uniform length boards

to obtain a shorter ceiling, resulting in speedier construction, and besides, higher ceilings were supposed to make the houses cooler. If you believe this bit of trivia ask some of the former residents who laid up

under the breeze-stifling mosquito bars night after night, with the perspiration rolling down their person.

The company houses, as a rule, all followed the same floor plan, with all being what was known as "shotgun style," because you could have fired a gun down the hallway in the center of the house, and hit someone sitting on

the throne in the back yard toilet. Each house faced a street and backed up on an alley, with an outhouse in the rear, next to the alley.

There was very little effort to maintain drainage of the town, so when there were excessive rains, water stood everywhere resulting in swarms of mosquitoes in spring, summer and fall. There were no screens on the windows,

but the commissary sold mosquito bars by the dozens, at a price.

There was absolutely nothing romantic about mill town life because management built the towns adjacent to the mills for easy access; this also brought an introduction to noise, fumes and debris from the saws, boilers

and smokestacks, with some form of dust permeating everything. Then, there were the inevitable steam whistles dictating your every waking moment, and would strike terror in every resident's heart when at night the whistles and

bells were used to warn of fire nearby.

The Masonic Hall featured some of Construction Foreman John Casey's finest workmanship featuring a huge Easter Star emblem over six feet in diameter emblazoned in the floor of one section of the top floor which was a

work of art. Casey used a variety of indigenous woods with different textures and hues to provide startling contrasts of the Easter Star hallmarks vivid colors. National and State office holders of the

Organization, on visitations to the Hall, were over whelmed at the obviously excellent artwork and craftsmanship involved.

The year 1907 was when management and labor got it all together. The labor force which worked in the logging woods were white, illiterate, local family men for the most part with their work uniform consisting of a floppy,

broad-brimmed hat, overalls and brogan shoes, all purchased at the company commissary. They took a bath in summer every Saturday night in the millpond, whether they needed it or not. From one "flathead's" own description, he

related that by the end of the week their overalls were so stiff with the rich resin off the crosscut saws, they would stand in the corner where you could just jump into them every morning and were also so slick that "a cat couldn't climb

a britches leg."

The company's work force, whether at the mill or in the logging woods, had to be in place when the whistle blew at 7:00 a.m. to begin a 10-hour day. They had an hour off for dinner and then worked until 6:00 p.m. Some of the

logging crews had to roll out on pre-dawn trains pulled by slow, powerful Shay locomotives. Often the woman of the house often getting up when the alarm went off at 4:30 in the morning and she'd have to get the wood stove

fired up to bake two big pans of biscuits. Then she'd fry bacon and eggs, for breakfast, and for dinner she'd put bacon, eggs, biscuits and some cane syrup in a lard bucket so the man of the house could set out walking, or

riding to the rail yard. Some crews had to travel from 20 to 30 miles, which necessitated riding a bench in boxcar. When they got in at night, often hours after dark, they then had to walk home to get a few hours rest and

then get do it all over again the next day, six days a week. Pairs of "flatheads" were required to fell 10 trees per day with these trees having to be cut up into logs 12 and 22 feet long to be hauled or towed to rail

side by the teamsters.

The teamsters were made up of two different classes. One was the muleskinners; the other group was the bull punchers. Mules were used mostly in the hills because they were faster, but oxen with their wide tired

eight-wheel wagons proved their worth in the swampy areas of the Buchanan holdings.

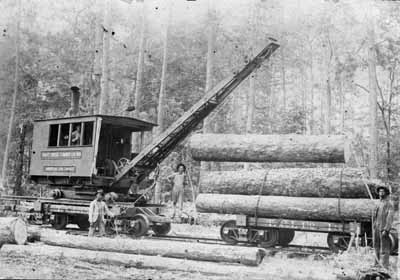

The loading of the one-ton logs at rail side onto the railroad cars was where life got dangerous and many men were hurt, maimed for life or even lost their lives. When a salesman of flatcar-mounted cranes asked one of the

company executives if the purchase of one of their devices wouldn't be better for the company? He was said to have replied to the salesman, "Hell No! That crane wouldn't trade at the commissary!" End of conversation.

The loggers, the teamsters and the loaders were the main components of the woods work force. To aid and abet these laborers were the rail gang that maintained the tracks and a small horde of youngsters that scurried around

the logging operations carrying water to the workers, and gathering pine knots for fuel for the locomotives.

Life rolled on in the town of Trout. In 1907 the first school was established on a hill back of Trout and the Superintendent was J.P.A. Whatley, and the first teacher was Commodore Walters. Dr. T.M. Butler,

formerly of Centerville (Summerville) came on board as another company Doctor. From 1907 to 1908 a Mr. Lynn was the office manager, then Charley North came back, and left again, and a Mr. O.F. Wyman took his place.

J.A. Buchanan retired in 1910 and W.J. Buchanan became manager of the mill. In 1912 a picture show was established in the Masonic Hall, and was managed by Ben Casey. It only operated for a few years. During the First

World War, nation wide business was at a standstill and labor was very hard to obtain.

In twenty-five short years, the Trout Creek Lumber Company had more or less cut out their share of the virgin pine forest from which the company ventures successes had been carved. Records indicate that in the operational

time period the mill had sawn over seven hundred million board feet of lumber. On the morning of March 1st, 1905 when the first log was sawn, operations had been almost continuous until October 4th, 1929, and the

company had employed from 350 to 400 men in the various departments. The last whistle was blown at the mill the next day, which was more or less a ceremonial rite, on Saturday morning October 5,1929, less than a month

before the Stock Market Crash. The Trout Creek Lumber Company mill had started work on a Friday and finished on a Friday.

The advent of the closing of a mill was nothing new to the Buchanan hierarchy. At this time William Buchanan had already been dead some six years. One company official recalled that when the Minden mill had been

consumed by fire in 1918, it fell his lot to go into the Big Man's office and inform him of the disaster. He knocked on the door and gained admittance, and told Buchanan the bad news. Buchanan looked at him for a

moment and calmly replied, "Son, that sometimes happens," and turned back around to his desk and resumed his study of a ledger.

The virgin long leaf pine forests William Buchanan had once ridden through on horseback were no more...

Rev.10/04 Jack Morgan Willis

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trout Creek Lumber's 3-truck 70-ton Shay No. 3 was bought new in 1918.

|

Trout Creek American log loader at work. The log cars were lettered "TCLCo". |

Otherwise unidentified Dickson 2-6-0 No. 50 have belonged to one of Buchanan's logging subsidiaries, Grace Logging Co. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lima 2-6-2 No. 45 also belonged to Grace Logging Co. |

Line of stored locomotives. |

Another Lima 2-6-2 at one of the Buchanan-owned mills near Jena. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

A logging crew and Trout Creek Lumber American loader No. 2. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ROSTER by Gil Hoffman:

Note: When first delivered, Number 2 pulled log trains

over the Louisiana & Arkansas Railway and was lettered “L. & A.

Ry.” and numbered “220” during the years of this service.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For more information contact Tony Howe at howe6818@bellsouth.net or David S. Price at dsprice46@bellsouth.net